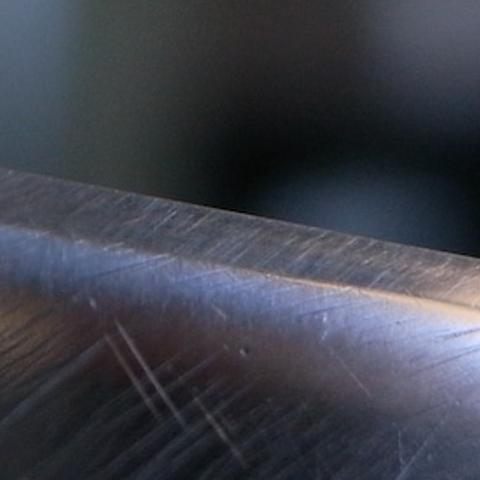

As you see in the image of the knife, the edge just make contact at heal and tip, with a big gap between the surface and the edge in the middle. This is a common damage for knives that has been sharpened on small electrical counter machines. The easiest way to fix this is to grind the edge down till it makes contact all the way on the side of a coarse sharpening stone.

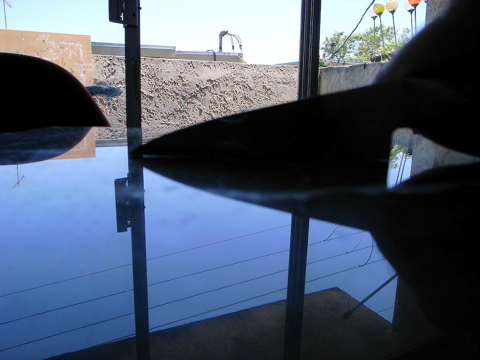

This is after the edge grinding, as you see the edge makes contact with the surface all the way. Time to start to recreate the bevel, for this I used a coarse DTM (steel plate with diamond particles embedded. After that I started the sharpening on Beston #500 until I got a good burr, to follow up with a no name #1000 stone, #2000 Bester, #5000 Naniwa and finally Kitayama #8000 stone.

The edge is straight, smooth and shiny, and you could see that it make contact all the way after the sharpening job.

Well the edge doesn’t look to shiny magnified x15 in real life it looks mirror polished.

Magnus Pettersson hand sharpener, now serving the whole Westside with free pickup and delivery: Santa Monica, Brentwood, Pacific Palisades, Venice, Marina Del Rey, Culver City and West LA.

For free pickup and delivery on the Westside, call/txt 310-486-6068 or email.