Knife sharpening with Nubatama ume 4000 and 6000

Testing Knife sharpening with the Nubatama ume 4k and 6k, are so different compared with the other stones in the series. First off they are both medium-fine stones, so I will mostly comment on how they feel and what kind of finish they leave. The 4k is medium hard and muddy, a lot like an Aoto. The 6k is hard, so hardly any dishing, no mud is just black swarf from the steel, a great pre-finisher. They both cut fast for their grit range, if any complaints the 4k leaves that green/yellow stain on everything. They both leave a very fine shiny if not mirrorish finish depending on the steel.

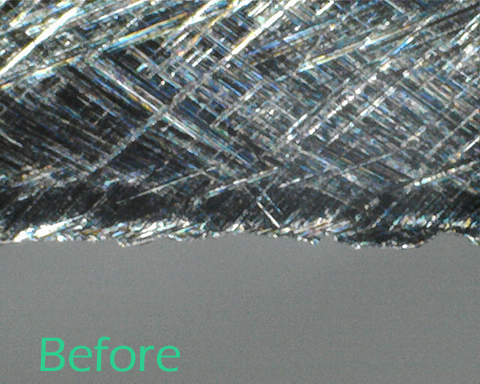

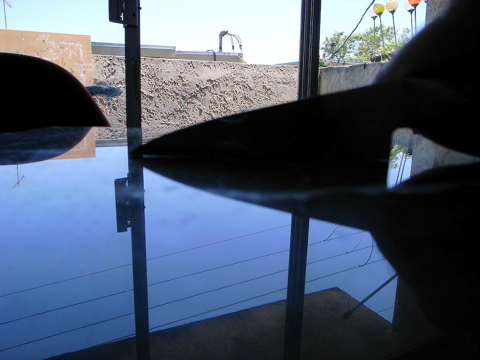

Knife sharpening progression

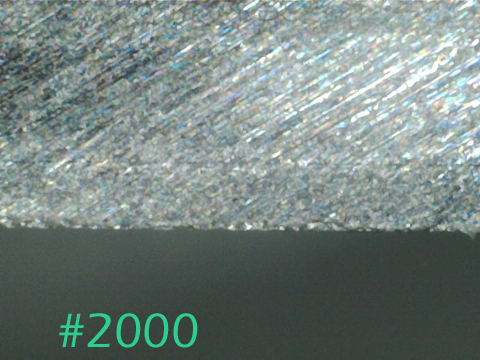

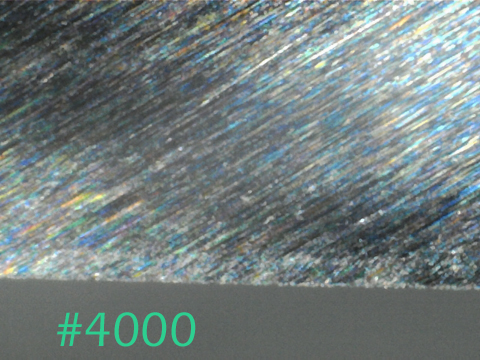

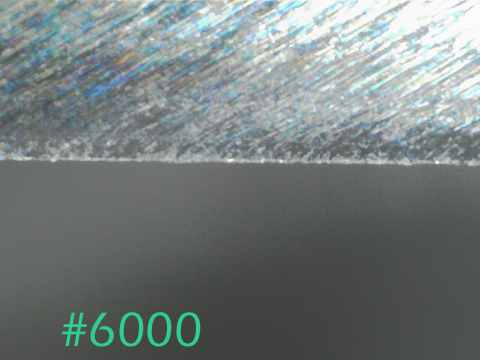

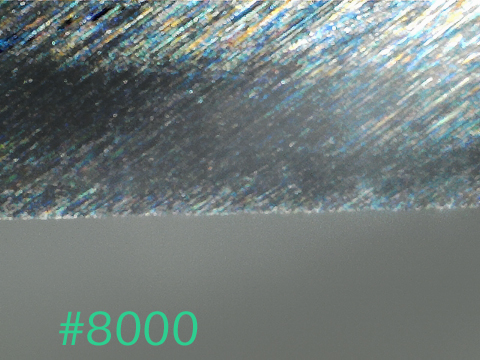

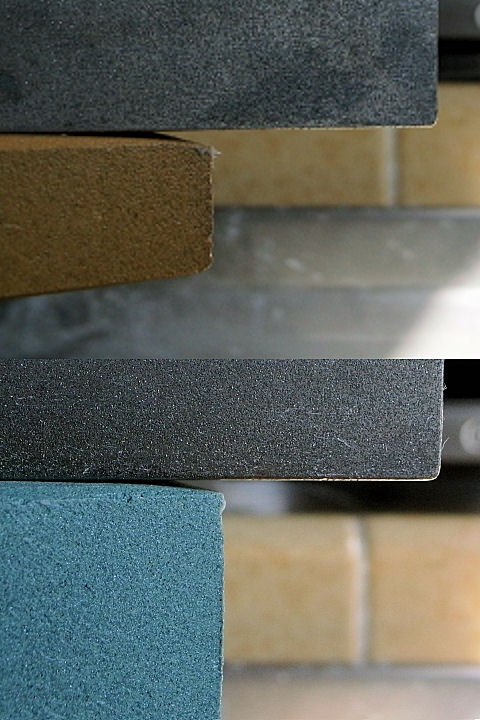

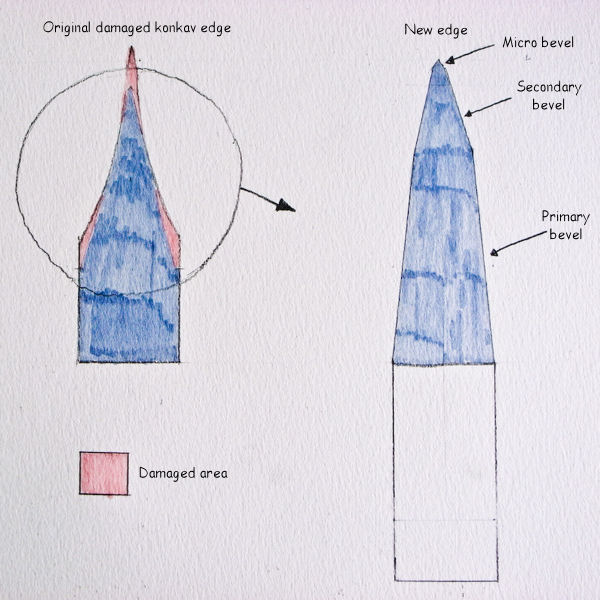

In the pictures below I will show the progression from unsharpened to strop, to demonstrate the whole knife sharpening progression, and where the Nubatamas fit in, in the progress.

As you see the use of Nubatama ume 4000 in the sharpening progression, does a fine job of refining the edge. It feels super smooth, cuts well and it doesn’t mud too much, and it is not rock hard so it still has great feedback. The finish it leaves looks surprisingly more polished than I would have thought; it feels and behaves like a Chosera 3000 stone. This would be a perfect final stone when sharpening soft steel knives.

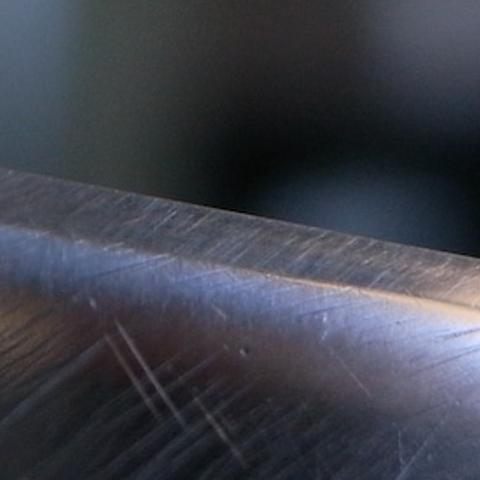

Knife sharpening with the 6000 is very different from the 4000, it’s harder, cuts slower, and in close-up it refines the edge with a slightly finer scratch pattern. The most surprising though is that to the naked eye, the polish from the 4000 looks better. At first, I thought I did something wrong, so I retested several times side by side with different knives and every time the 4000 left a better finish to the naked eye, but in close up the 6000 had a slightly better finish. Speculation could be that they have different abrasive densities or different kinds of binding material. If I continue to finer stones, the result of the 6k is better.

They both clean up well on finer grit stones, but the 6k is a better pre-finisher.

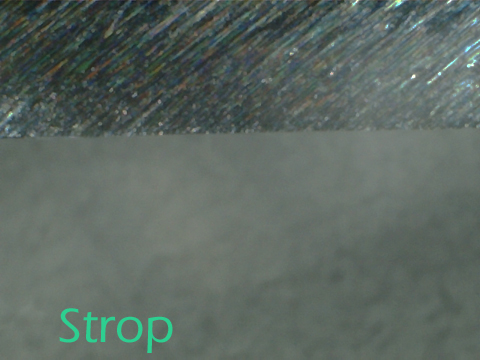

Edge after a fast tour on the leather strop.

Conclusion:

I see no need to buy both of these stones for knives because they are not that different. I love the 4000; it is a really nice, fast-cutting stone that leaves an awesome finish. The only thing I don’t like is that green/yellow color that stains everything. The 6000 is also a really good stone that leaves a finer scratch pattern. Its hardness and low mud make it perfect for straight razors.

Magnus Pettersson hand sharpening in Santa Monica. 1-310-486-6068