Santa Monica Knife Sharpening blog explains, when to have your knife hand sharpen and when to buy a new one.

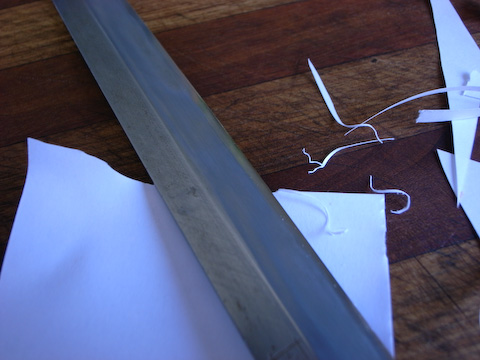

A lot of this will be my personal opinions. Usually if you don’t have extremely high quality serrated knife, I would recommend buying a new one instead of getting it sharpened. Example if you have an old 8 inch bread knife, like the one in the picture below. Pro sharpeners would charge around $9 plus $1 per inch of serration, so the total fee of the sharpening job would be around $17

Old serrated bread knife

For $11.95 you could buy J.A. Henckels International Fine Edge Pro 8-inch Stainless-Steel Bread Knife in the picture below. That I’m sure has both higher quality and a better, sharper edge than anything a pro sharpener could accomplish on your old cheap serrated bread knife and it would save you a few dollars.

New cheap serrated bread knife

Old stainless boning knives, like the one in the picture below. Many times they have been along for a long while, sharpened down to a stick, beaten, sharpened again.

Old boning fillet knife

I’m sure they might have been ok knives once, but after all that abuse and wrongful sharpening, they are not very useful for anything. You will do better in investing in a new knife, like Victorinox 47513 6-Inch Flex Boning Knife for $17.41 bellow.

New cheap boning fillet knife

It will have better edge geometry, better harder and more flexible steel and have way better edge retention. As for buying both boning/fillet knives and serrated knives I actually recommend to buy cheap decent quality knives, and save the money to buy a better chef knife and paring knife.

Small guide to buying new knives

1. Don’t buy a knife set, you will probably just end up using 2-3 of the knives any way, use the money to buy better quality chef, slicing and paring knife instead.

2. Most important, make sure the handle works for you. It should fit well in your hand, not being to slippery and give a sense of stability.

3. Choose the right length for your chef knife, your wife wife might prefer a 6” knife and you a 10” knife, an 8” inch would work okay for both of you.

4. Think of how you cut, I’m a rocker so I prefer to have a good bow on my knife, my friend is a push cutter and prefer straighter edge.

5. Choose a knife with high quality steel, high carbon steel knife if you don’t mind some stains and are good on keeping it clean and dry, or a high carbon stainless steel if you are less careful with your knife. Usually the harder steel they sharper the knife could be and softer steel will take a little more abuse. I personally prefer extremely hard Japanese knives.

6. Think about if you prefer a bolster on your knife, some people like the heft it gives the knife. I personally don’t like it and have removed it from the knives I have that had it. Mostly because it makes the knives to front heavy, hard to pinch properly and a real pain to sharpen. Most German knives have bolster, and it is rare to see on Japanese knives now more.

7. Avoid Cutco knives, they are a rip off, they are $25 knives that they sell for a $100, no wonder they could give great warranties with that mark up. Good and affordable knives brands are; Global, Shun, Tojiro and Mac. If these are too much for your budget I would recommend Forschner knives that a great knives for the price.

How to maintain your knives

1. Use the right knife for the right duty, slicing knives for slicing, chef knives for chopping and dicing and paring knives for light duty.

2. Always use a good end wood or nylon cutting board, no cutting on counter, plates and ceramic cutting boards.

3. Always rinse them and dry them off right after use, don’t run them in the dishwasher, don’t let them lay in a dirty sink and so on.

4. Don’t use any kind of electric home knife sharpener, they ruin your knives.

5. Don’t steel your knives if you don’t know how to steel, you just make the knives duller.

6. Keep your knives sharp, and sharpen them before they go dull. If you keep on working with a dull knife you just use more and more force and damage the knife more.

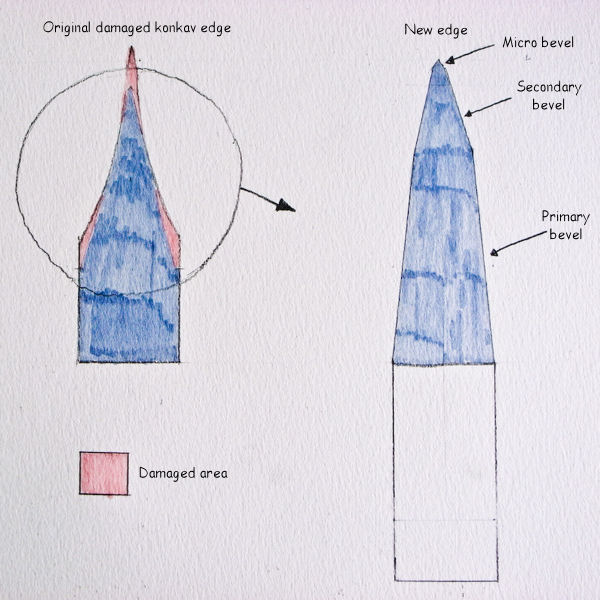

How to sharpen you knives

Get a Japanese combination water stone #1000/#5000 grit, and practice using it on some cheap knives first. There is tons of information online how to do it right, watch a few you tube videos and read up on some of the theory behind sharpening. After just a few hours I promise you will be able to do an ok sharpening job, the knives will be far from razor sharp and will not stay sharp for very long, but will be good enough for kitchen use and with time you will get better and better. If you don’t have the time or feel like sharpening your knives yourself try to find someone that do hand sharpening.

What kind of knives you need

I can’t answer what knives you need, it is rather personal, but for a start I would recommend.

1. A medium size chef’s knife, as a Global G-2 or MAC Superior 8″

2. A decent paring knife like Tojiro DP or Calphalon Katana

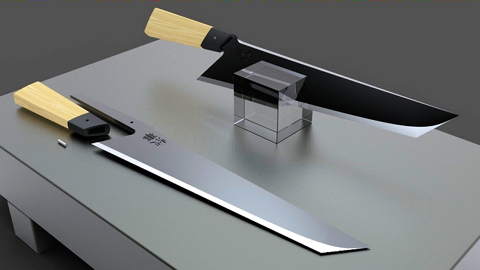

3. A good single bevel Japanese slicing knife (Yanagiba) they are great for precision slicing any meat.

Magnus Pettersson hand sharpener, now serving the whole Westside with free pickup and delivery: Santa Monica, Brentwood, Pacific Palisades, Venice, Marina Del Rey, Culver City and West LA.

For free pickup and delivery on the Westside, call/txt 310-486-6068 or email.