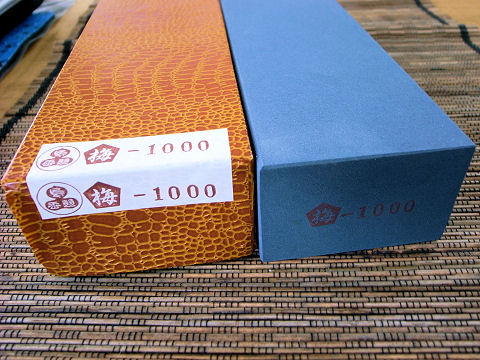

Nubatama ume 1000 grit review

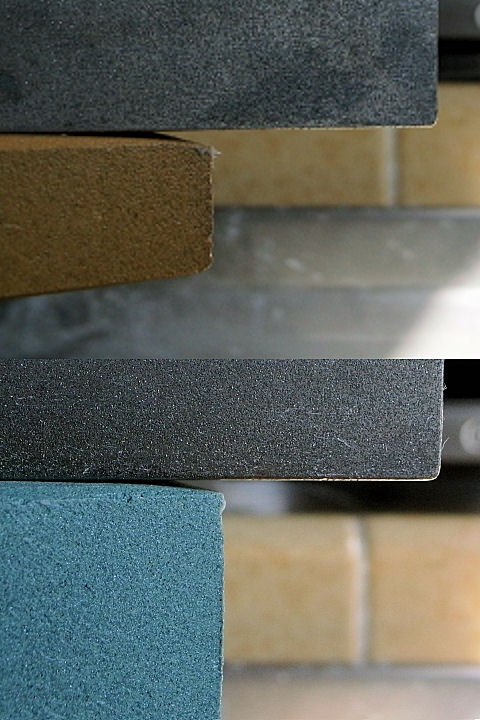

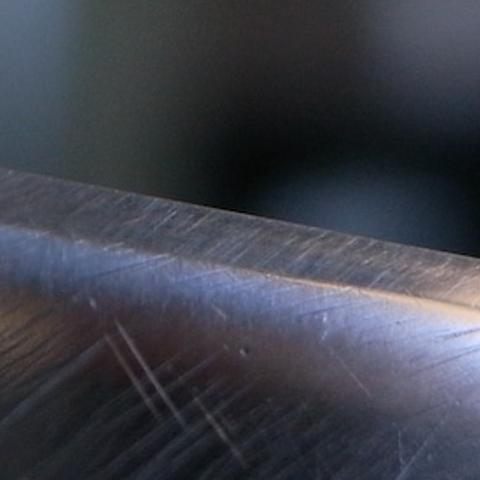

I don’t know what to say, this was supposed to be an ordinary review, stating the facts and impression of the stone. Fist off it isn’t like any other 1k stone, it feels porous, have a beautiful deep blue color, sounds porous dry, and feels more like a lower grit stone to the touch. My first thought was to compare it to some other very common stones in this grit range, like Sigma ps, Shapton pro, Beston and Chosera.

The second thought was to compare it to some cheap clay stones and I realized that the Nubatama would eat them alive so that would not be fair. Third thought was Chosera 1k, but I don’t use it anymore, because I usually go straight to Bester 2000 wish is my everyday midrange stone. Well after the Nubatama 320 retired my Bester 500, maybe I should compare it to Bester 2k instead. I love Bester 2k, I know even before I start that I will still love the Bester in the end, and that there is no way that I will retire it.

Nubatama ume 1000 vs. Bester 2000

- Size: Nubatama wins it’s twice the size

- Dry out time: Bester 2k wins 3min 10sec and just 2min 26sec for Nubatama

- Cutting speed: Nubatama wins it’s not twice as fast, but definitely much faster

- Dishing: None of them dish much, but Bester dish slightly less

- Finish: Bester 2k wins, it leaves a much clearer finish

- Feel: I love the feel of Bester 2k, but with mud build up Nubatama feels super nice just in a different way.

Ok I realize that it isn’t a fair compare, I love the Bester and the grit is too different to even try to compare them. I went and got my old favorite Chosera 1k, to see if that is a better match up.

Nubatama ume 1000 vs Chosera 1000

- Size: Nubatama wins it’s twice the size

- Dry out time: They are both thirsty stones but the Chosera wins with a tiny 10sec

- Cutting speed: Nubatama wins but not with much, my guesstimate is 5%-10% faster

- Dishing: Nubatama wins but not with much

- Finish: Chosera wins it has a better finish

- Feel: They both feel awesome but very different; I had almost forgotten how smooth the Chosera felt so this is more a matter of taste.

- Clean up on higher grit: I give it a slight edge to Chosera, but it is not as much as I would have thought.

Would I replace my favorite Bester 2000 with Nubatama ume 1000, no I would not. Would I choose Nubatama ume 1000 over Chosera 1k. Yes, I would because it is twice the size, dishes less, and doesn’t have that green mud that stains everything. If you care about finish in this grit range, Chosera might be your choice.

Conclusion:

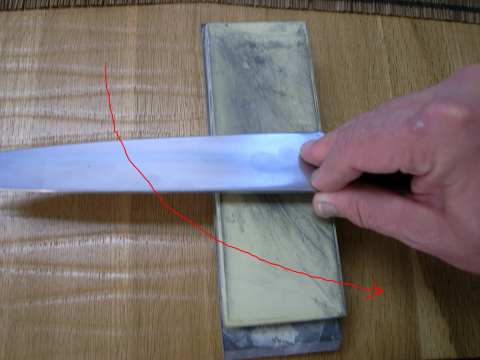

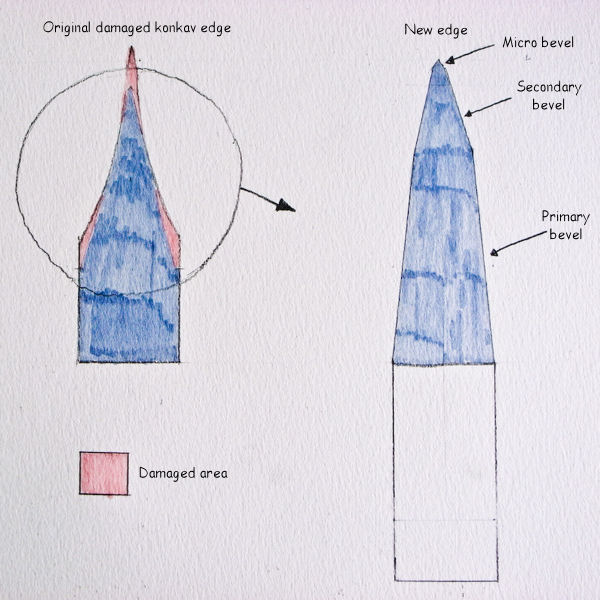

Nubatama ume 1k isn’t a metal-eating beast like Sigma 1k, but it cuts faster than most other 1k stones. It doesn’t dish much and you get a big stone that will last you a while. What is amazing about sharpening on this stone is hard to put down in facts. It is a matter of feeling, after building up the first mud with another 1k stone, it has the magic. That magic feel and sound that makes you drool, awakens that warrior sharpening his sword deep inside, that have been hidden for a long while.

You slow down and close your eyes, hear and feel every stroke against the stone. It makes you feel how the power almost makes your beam energy. Everything else around you disappears. That edge is taken from sharp metal to an edge that will carry a piece of your soul forever.

Do I have to say more, I love the feel of this stone. Now I just have to find use for it. I might end up using it as a step-up stone after Nubatama ume 320. If someone was just buying a single stone to keep their knives sharp, I would definitely recommend Nubatama ume 1k as.

Magnus Pettersson hand knife sharpening in Santa Monica, call or text 310-486-6068 or email.