What you need to do before you can sharpen your knife

Start with making sure that the knives are clean, and straight, also determine if they have chips or other damages that need attention. You also have to check if the edge bevel is straight, with the correct angle for the knife. All of this needs to be corrected before sharpening could begin. Straighten and do all repairs, for this, I recommend a really coarse DMT plate which makes it fast and easy, and for bevelling something in the 500# grit range is perfect to set the initial edge.

Putting the correct angle on the knife

Before starting, prepare the stones and make sure they are flat and clean. Find the right bevel angle for the knife, somewhere between 15-20 degrees is a good starting point. An easy way to find the angle is to measure the height of the blade at the heel, let’s say that your knife is 2” high at the heel, as in the picture below.

Measuring knife blade height at the heel

In this case, you could just divide the height of the blade, to get an estimated height that you need to hold the spine above the stone. Below I have a large heavy-duty knife of bad quality so I decided to give it an obtuse edge angle of 30°. I divided the height of my blade by 2 and that tells me that I have to hold the spine one inch above the stone, see the picture below.

Measuring knife spine distance from stone

Here is a table of rough estimates of values to divide the blade height for different angles.

For 30° divide by 2

For 24° divide by 2.5

For 20° divide by 3

For 15° divide by 4

For 12° divide by 5

The knife sharpening process

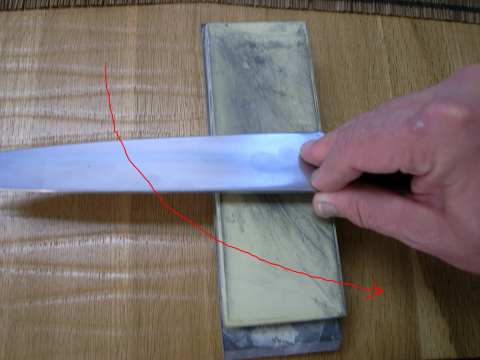

When you have fixed everything you need and the angle is right you can start sharpening. I usually start with a coarse stone 700# grit till I get a smooth straight even edge with a burr. Next, I continue with a medium stone in the 1000# – 2000# grit range making sure that I keep it tight and have a light burr. I usually hold the knife diagonal over the stone to avoid wobbling, see the picture below.

Santa Monica hand sharpening knife diagonally to avoid wobbling

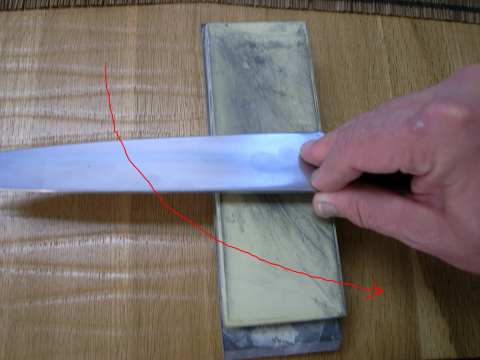

After this I deburr with some light edge trailing strokes on both sides and a few slicing strokes on a cork or a piece of wood, before moving on to the finishing stones.

Edge tailing strokes on fine sharpening stone to deburr

Deburring knife edge on cork

Finishing the edge to your desire

Usually, I start the finishing work with a fine stone in the 4000# – 6000# grit range. While using lighter and lighter pressure, this stage it’s a lot about feedback. What does it sound like, does the water roll up on the edge evenly, and so on? If the groundwork has been done correctly on the coarser stones 10 strokes per side should be enough. This should be enough for most ordinary kitchen knives, just deburr on a cork. At this stage, you should be able to shave with the knife with a little bit of pressure.

If you want you could continue with super fine stones, but that is pure vanity. I most often only use a 8k# and 12k# stone to get that shiny mirror finish. Of course, you could continue to refine it even more, but that is more for straight razors.

Things to remember

- Make sure the stones are flat and clean.

- Don’t use too much pressure, let the stones do the work.

- Avoid doing it too fast, so you don’t wobble.

- Try your best to keep the angle, after a while it will come naturally.

Magnus Pettersson hand knife sharpening

1423 Euclid Street, Santa Monica, CA 90404

To request knife sharpening call or text 310-486-6068 or email.

Please follow me on Instagram @santamonicasharp